LED Panel Light: Are All LED Panels the Same?

LED Panel Light: Are All LED Panels the Same?

What is LED panel light: it is also known as flat panel light, a kind of light fixture that uses an LED light source and is surface-emitting. The LED panel light is a high-end indoor lighting fixture. Its outer frame is made of aluminum alloy and anodized with paint spraying. The light source is LED. The design of the whole lamp is vigorous, elegant, and luxurious. It not only has good lighting effects but also brings people the feeling of beauty and comfort. The LED panel light is unique in design, the light passes through the light guide plate with high light transmittance to form a uniform plane luminous effect. The light uniformity is good, the light is soft, comfortable, and bright, which can effectively protect from eye fatigue.

The LED panel light can also prevent radiation and will not irritate the skin of pregnant, the elderly, and children. It is suitable for many applications:

Office buildings, conference rooms, shopping malls, classrooms, laboratories…

Features of Logos Lighting’s LED Panel Light:

1. Uniform light effect;

2. Ultra-thin design, the thickness is only 9mm;

3. Full range product series, including but not limited to edge-lit LED panel light, backlit LED panel light, CCT tunable LED panel light, RGBW LED panel light, waterproof LED panel light, etc.

4. Different installation methods available;

5. Elegant appearance;

6. Approved CE and RoHS certifications.

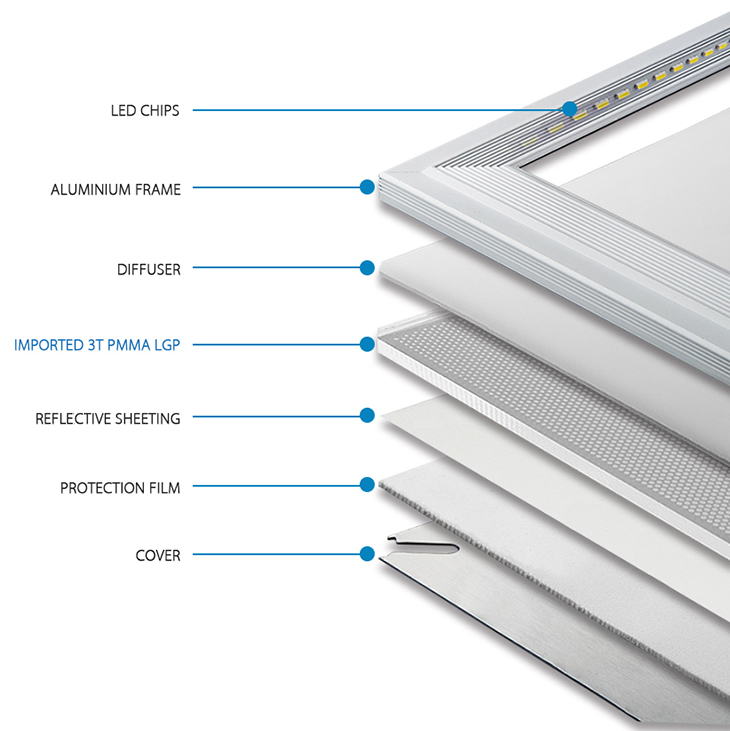

Here is a brief introduction of the main components of LED panel light

1. LED Panel light aluminum frame:

The LED panel light aluminum frame is made of 6063 aluminum with extrusion technology, machined with cutting, stamping, and other processes, then connected with four corners.

2. LED light source:

The LED light source are 2835, 4014, and 5050 most popular for LED panel light. At present, our company’s LED panel lights are used mainly 4014 and 2835. The light guide plate is 2MM or 3MM. For the 2835 LED light source, the light guide plate is used with a thickness of 3MM. 5050 is generally used for RGBW LED panel lights, that is, colorful LED panel lights. The light guide plate should be thicker.

Important LED parameters: current, VF, color temperature(CCT), CRI, color tolerance, light efficiency, etc.

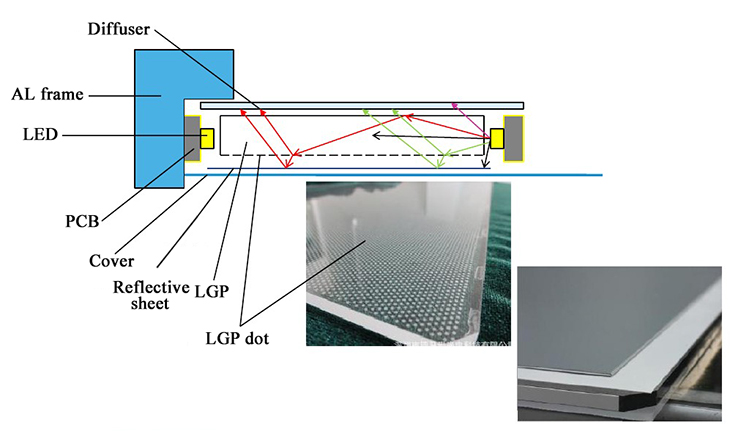

3. LED light guide plate(LGP):

The side LED light is refracted through the dots of LGP so that the light is exported from the front uniformly. The light guide plate is the key point of the quality control of the LED panel light.

If the dot design is not good, the overall light effect is very poor. Generally, there will be light in the middle and dark on both sides, or there will be a bright light band at the sidelight entrance or a partial dark area, or there may be inconsistent brightness at different angles, and the light effect is also affected a lot. To improve the transmittance light efficiency of the light guide plate, it mainly depends on the design of the dots, followed by the quality of the plate. Generally, LED lamp factories will customized light guide plate and testing to meet the factory standard requirements.

Light guide plate production method:

At present, there are printing, engraving, chemical etching, direct injection molding, and even light production methods.

The material of the light guide plate:

Commonly used are PMMA, MS, PS, and other products. PC can be used for particularly high-demanding applications. The price is quite high, and it is basically not used in the market. Secondly, the price of PMMA is cheaper than PC, and the light transmittance is higher than PC, but the wear resistance and stability of the PMMA are not as good as PC. The price of PS is cheap, and the light transmittance is also high, but the abrasion resistance and stability are relatively poor.

You can learn more about plastic materials via Plastic Materials: What’s the Difference Between PC, PMMA, and PS?

4. LED diffuser:

The diffuser can lead out the light of the light guide plate uniformly, and it can also blur the dots.

Generally, the diffuser plate is used PS material.

5. LED reflective paper:

A reflective paper is usually referred to as reflective film, which is a high-tech product. The main function is to use the unique properties of the reflective material of the reflective film to reflect light in the direction of the light source. The reflective film is a novel reflective material formed by combining the reflective layer formed by glass beads with polymer materials such as PVC and PU by using a special process.

6. Rear cover:

The main function is to shading, reflecting and protecting, etc.

7. LED driver:

The LED driver is an important part of the LED lamp. It is a bridge for the voltage conversion between the LED panel lamp input and the mains output. The matching between the driver and the LED module directly affects the lamp’s work, life, flashing and burnout, etc., and other phenomena.

7.1. LED power supply can be divided into two categories according to the driving mode:

A. Regulated type:

After the voltage regulator circuit determines the various parameters, the output is a fixed voltage, but the output current changes with the increase or decrease of the load;

Although the voltage regulator circuit is not afraid of load opening, it is strictly forbidden to short-circuit the load;

The voltage change after rectification will affect the brightness of the LED;

To make each string of LEDs driven by a voltage stabilizing circuit with uniform brightness, you need to add a suitable resistance.

B. Constant current type:

The constant current drive circuit is an ideal choice for driving LEDs. LEDs are current devices.

Although the constant current circuit is not afraid of load short-circuit, it is strictly forbidden to open the load completely

The output current of the constant current drive circuit is constant, but the output DC voltage varies within a certain range with the size of the load resistance.

Limit the number of LEDs used, because it has the maximum withstand current and voltage value

7.2 There are various kinds of LED drivers on the market, including flicker and no flicker, high power factor(PF), and low power factor(PF), with dimming and no dimming. 0-10 dimming, DALI dimming, Triac dimming, PWM dimming, RF dimming, etc.

LED panel light specifications

There are many types of flat LED panel lights, and different countries have different sizes. Different customers in the same country may also have slightly different specifications.

Below are actual dimensions of LED panel lights in some countries:

The actual size of USA LED panel lights: 603*603, 301*1212(2981213), 301*603(298603), 603*1212(6031213)

The actual size of the Germany LED panel light: 620*620 is mostly, 595*595 is less, and the other specifications are the same as other European countries.

The actual size of Korean LED panel lights: 640*640, 320*1280

The actual size of LED panel lights in other countries: 595*595, 295*1195, 295*295, 295*595, 595*1195.

Because other countries use most LED panel lights, and the Chinese market also has these sizes, they are also called 600*600, 300*1200, 300*300, 300*600, 600*1200 as convenient.

Installations of flat LED panel light

1. Embedded

The recessed ceiling has a standard size ceiling and keel. When installing, you only need to remove the corresponding ceiling and replace it with the corresponding LED panel light. No additional installation accessories are required, and the installation is very convenient.

Embedded-1 Directly embedded

Embedded-2 Card keel type(clip-in)

2. Spring type

Similar to the installation method of downlight, it is necessary to open a hole on the ceiling (smaller than the size of the panel light), and then embed the LED panel light in the hole with springs. Springs accessories are needed to be installed.

3. Hanging type

It is suitable for all sizes of panel lights with a high floor height, and the ceiling is a solid wall structure.

The lamp is hung in the room with a sling, and accessories need to be installed.

4. Ceiling mounted type

The ceiling is a solid wall structure, first install the ceiling piece or frame on the wall, and then lock the lamp into the ceiling piece or frame.

Ceiling type-1 Ceiling frame-mounted: The LED panel light is mounted with an aluminum frame accessory.

Ceiling type-2 Direct ceiling mounted: The LED panel light can be mounted directly on the ceiling.

If you have any questions about flat LED panel lights, welcome to contact us directly.