The Top First Reason For LED Luminaire Failure and Degradation

The Top First Reason For LED Luminaire Failure and Degradation

Heat is the number one reason for LED failure and degradation.

While most LEDs are durable enough to operate in extreme environments, it will greatly decrease their life. LEDs don’t usually die, but they degrade at a predictable rate and heat accelerates this process.

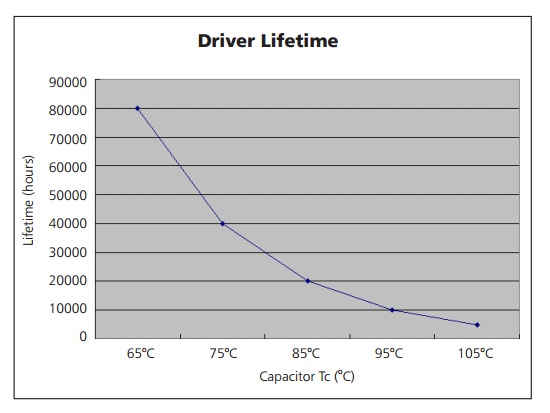

LED Drivers are sensitive to heat, too. In fact, if a LED lighting fixture seems to have failed completely the first problem to check for is a failed driver.

Where does the heat come from?

The LED chips create a significant amount of heat. Because the LEDs do not produce infrared radiation like traditional lighting, many believe that no heat is produced; this is incorrect. To create light, electricity is passed through a mixture of phosphors and other chemicals creating heat as a byproduct.

The driver, just like any other power adapter, heats up significantly. Think about your laptop charger as an example.

When heat is introduced by environmental factors, like sun or ambient heat, dissipating the heat produced by LED components becomes increasingly important.

Possible ways to handle the heat:

● Separate the driver from the LED chips. In some cases separating the heat sources will be enough to eliminate the need for more costly heat mitigation measures.

● Fixture coating with a polyester powder coat finish – protects the fixture from extreme temperatures and allows for better heat dissipation.

● Heat sinking fins with slots between the fixture can help facilitate convection by increasing surface area and allowing airflow.

● Making slots vertical on the heat sink and fixture will limit dust collection. Dust acts as an insulator and should be removed periodically.