Do You Really Understand LED Lifetime? Read This!

Do You Really Understand LED Lifetime? Read This!

LED technology started in the semiconductor industry, but is booming in the lighting industry. As a newborn thing, it is facing many questions and discoveries. LED is famous for its extra-long lifetime. However, how we can predict the lifetime without any convincing tests? Is there any difference in LED lifetime with the traditional lighting source? Comparing LED with traditional lighting and analyzing the latest standard development meanwhile, hope it will help you understand what the lifetime stands for really.

1. LED development background

The life of traditional light sources is mainly determined by the life of the filament. The principle of semiconductor light emission of LED itself, without filament, determines its long life. Coupled with its own low power, the world with increasingly tight energy and greenhouse effects has found another breakthrough in energy-saving and emission reduction.

2. LED life confusion

The life of the LED is the guarantee of all other advantages. The earliest publicity is that LED life is 50,000 hours or more. When our manufacturers are hyping how good their products are and how long they last, our end users may not even feel the advantages in this regard. The reason is that one is that there is no intuitive user experience for customers of such innovative products, the other is that poor products with price for the market make it impossible for customers to continue to use it, and the three exaggerated data without sufficient experimental basis Consumers can’t believe it easily. Fourth, is it really unnecessary to replace it because of its long life? In addition, LED originally belongs to the semiconductor industry, plus the characteristics of the semiconductor product itself, the definition of life are subject to various factors As well as the rapid recognition of continuous improvement, not only ordinary customers but also professionals in the traditional lighting industry have a feeling of being in the clouds. What kind of LED does our traditional lighting manufacturer choose to ensure the life of the system (light source, lamp)? How to choose it?

In summary, the life of LEDs is no longer as simple to understand as traditional light sources, and new areas are still being explored, with many concepts and lack of practical experience. The purpose of this article is to explain the life of LEDs with a standardized field of view, to clarify various relationships, to help lighting companies using LEDs to know how to choose reliable LEDs, to make reliable systems, and to help end consumers when choosing LED products.

3. The life of traditional light sources and the effective life of LED lumen maintenance

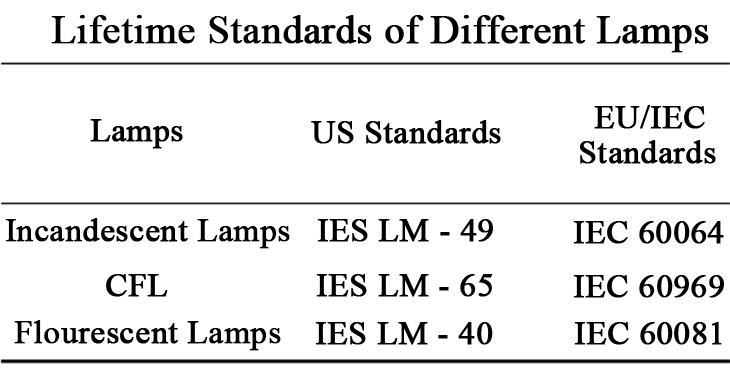

Before understanding the life of a distinctive LED, let us first understand the life of a traditional light source. Traditional light sources use widely accepted methods to determine their rated light source life. These methods have been given in various standards in below table.

The standard specifies the test environment, sample selection, and test methods. For compact fluorescent lamps, for example, the standard specifies that samples must be tested in a 25 ° C environment. One test cycle is 3 hours on and 20 minutes off. The time when half of the light source fails is the rated average life of the light source.

Unlike LEDs, traditional light sources do not use lumen maintenance to measure life. What is the reason? For tungsten filament light sources, the luminous loss is mainly due to the filament loss. Generally speaking, the luminous flux loss of tungsten filament lamp is only 10% ~ 15% of the initial luminous flux within the average rated life of 1000 hours. For fluorescent lamps, the luminous loss is mainly due to the photochemical attenuation of the phosphor coating and the glass tube. For compact fluorescent lamps CFLs, the luminous loss does not exceed 20% of the initial luminous flux within its average rated life of 10,000 hours. For high-quality lights T8 and T5 using rare-earth phosphors, the luminous flux loss does not exceed 5% during their 20,000-hour lifetime.

For LEDs, there are various reasons for the possibility of light attenuation according to the production principle. For example: drive current, junction temperature, phosphor, lens, etc. Due to the long theoretical life of LEDs, it may take many years of testing to make them “point-bad”. And unlike other traditional light sources, even if the light decays to 50%, it can continue to light. But can the light at this time still meet the requirements of lighting design? Therefore, lighting designers need to know exactly what they can emit no less than the effective luminous flux and can meet the life span of their design, not their “point broken” Lifetime, to accurately calculate the cost of installation, maintenance, replacement and comparison with traditional light sources. Based on the above reasons, the life of the LED is often calculated by the effective life of the lumen maintenance rate.

4. LED component life

4.1 Range of LED

Before giving the life of the LED, we must first determine the scope of the LED. We often hear that LEDs actually include LED components and also LED systems. LED components are common LED chips, and the system is the end product of LEDs used by users, including light sources, modules, lamps, etc.

4.2 LED component life, L70, L50

Definition of life: what is life? We need to define it clearly. The European standard system is mainly based on the IEC standard and is issued by the International Electrotechnical Commission IEC. The US LED standard system is relatively complicated. The different standards are administered by the North American Illuminating Society IES, the American National Standards Institute NEMA, and the American Underwriters Laboratories UL.

L70: The luminous flux maintenance rate of the LED lamp (module) meets the requirements of this standard and can continue to light up to 70% of the cumulative time when the LED lamp (module) reaches the life of a single LED lamp (module).

The IES standard links life to lumen maintenance and gives a new understanding of life. We will see later that using this data we can infer the true life of the LED-based on the data available for a period of time. So to some extent, the rated lumen maintenance life given here can be understood as the useful life of the LED. By standard, it relates life to lumen maintenance. The life of the LED itself is determined by the light decay to 70% of the life. This period of time is relatively short compared to the time to failure, and it is easier to operate. It also shortens the research and development test time when LEDs are replaced. More and more LED manufacturing companies have begun to use L70 to nominal LED life.

4.3 B50, B10

In the actual operation process, we found that when the L70 test of batch samples, due to a series of factors such as process and materials, there are differences and different reliability among individual LEDs, such as extremely low lumen maintenance or damage. Taking into account the actual possible defective rate, the concepts of B50 and B10 were introduced.

B50 L70 indicates that the lumen maintenance rate of the LED under this life is not less than 70%, and the luminous flux of 50% of the LED is calculated to be less than 70% or damaged.

B10 L70 indicates that the lumen maintenance rate of the LED under this lifetime is not less than 70%, and the calculated luminous flux of 10% of the LED is less than 70% or damaged.

4.4 TM-21

LED light decays to a certain extent, it can continue to emit light, instead of immediate damage as we usually understand. It may be that the LED is not damaged like a traditional light source at this time, but its luminous flux can no longer meet the requirements of lighting design. Designers need to understand this life. This requires an operable method to infer the life of the LED. Since the data of the lumen maintenance rate according to the LM-80 is already available, along the way, I would like to know whether the final life of the LED can be derived based on the LM-80 data. -21 standard.

TM-21 is based on the data obtained from the IES LM-80 test to estimate the long-term lumen maintenance rate. TM-21 stipulates that the lifetime derived from LEDs must not be longer than 6 times the LM-80 test time. The deduced time is expressed in the form of Lp (Yk). P is lumen maintenance rate, Y is LM-80 data acquisition time (unit kh). Example: L70 (10k)

Both the LM-80 and TM-21 that we mentioned earlier are standards for LED component life. But for the LED system of the final product, further work is still needed to answer.

4.5 LED Life and Temperature

As we know, the life of LED is also closely related to temperature. LED junction temperature is an important indicator of its performance. According to LM-80, the manufacturer’s test temperature is three Ts temperatures under the same driving current (Ts refers to the temperature specified by the manufacturer that can be tested with thermocouples on the LED package), that is, 55 ° C, 85 ° C, and The temperature determined by the manufacturer according to the possible application. Then based on TM-21 to infer the life at various Ts temperatures.

5. LED system reliability and life

The true reliability and longevity of LED lighting systems are not generally known. To make matters worse, we often use the lumen maintenance rate of LED components as the life of the LED system. The lumen maintenance rate of LED components is only one of the reliable components of LED systems. In fact, the life of a well-designed and manufactured LED lighting system is not determined by the light decay of the LED.

Regarding the life of LED luminaires, it usually contains many interconnected parts and subsystems, each of which has a different life and reliability. It is generally impossible to use their worst or best values directly, but they need to be evaluated as a whole to consider their interactions.

For LED systems, insufficient light output is no longer the only reason the system needs to be replaced. It is also necessary to consider light color drift and changes in light distribution when some LEDs are damaged. According to LM-80, it indicates the importance of color and requires that the test report should give the color drift at the test time.

The components you can choose when designing have the same long life as LEDs, but this is often not the most cost-effective. The feasibility goal of a system long-life design is to find a balance between data possibilities and costs. That is, at a reasonable cost, the designed system has a failure rate within an acceptable range in the expected life. Reliability and life are two important measures of the effective life of an LED system.

For LED lighting systems, three main aspects affect reliability:

Design flaws: mainly include poor thermal management, use of mismatched chemicals that can cause lens or chip light attenuation, poor LED drive, chip overload, poor packaging that can infiltrate water vapor, etc.

Manufacturing defects: This type of defect cannot be eliminated, and it mainly occurs in early failures, especially as production increases. Manufacturers can reduce such defects through factory testing and aging.

End of life: Failure of some key components in the system will render it unusable. We need to choose the right components and to reasonably estimate the life of the system.

It is very complicated to determine and evaluate the life of LED lamps by observing the long-term light decay method. At the same time, when people are more and more aware of the shortboard of LED system life lies in the LED control device. The life of the control device is mainly affected by the life of the electrolytic capacitor used. The electrolyte in the capacitor will volatilize to varying degrees with the working temperature and working time, and the capacitor ripple current will also affect life. A 10-degree increase in capacitor temperature reduces life by half.

Read Will Electrolytic Capacitors Really Cause Short Lifespan of LED Lamps? for the details.

For many reasons, it is difficult to give the life of LED lighting products. However, at the same time, consumers need to understand their lifespan, make a calculation of factors that affect the transaction’s energy efficiency, maintenance costs, initial investment, etc., and then make an informed decision when considering whether to buy an LED product.

In summary, here discusses the life of LED components and LED systems based on the current understanding of LEDs and the development of standards. Hope that this will help you have a better understanding of the lighting industry.

If you have any questions, welcome to contact us directly.